Outside of a few specific applications, pistons have been the heart of the internal combustion engine. The technology for these short cylinders within the tight tolerances of modern race motors has come a long way from the roots of even classic muscle cars. Today there are a number of manufacturers pushing the envelope in terms of design while also providing custom specifications for engine builders.

In the 1920’s the Mahle brothers, Hermann and Ernst, countered the heavy, cast-iron piston with a then-revolutionary alloy piston that was far lighter. MAHLE continues to be the name in piston technology, as more than half of all automobiles built today have MAHLE pistons. The company is also one of the few who still performs all development and production of key components inhouse.

“We were first attracted to the MAHLE Pistons because of their high tech coatings,” says Cliff Moore, general manager Jon Kaase Racing Engines. “They were one of the first pistons so equipped. It was, and still is, a very good looking part, and we receive great performance and durability. We first used the pistons in the Southern All-Stars circuit that was similar to the Hooter Cup that was to follow. It was from that experience that we gained confidence in their quality and power building capability.”

PowerPak Piston Assemblies

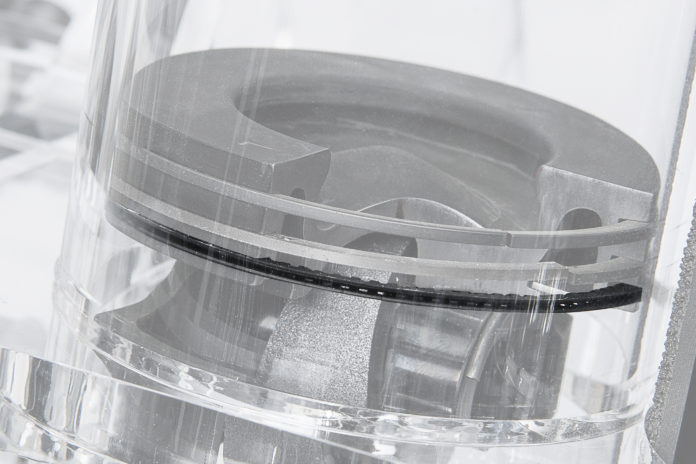

MAHLE’S PowerPak piston assemblies are available in both high and low compression applications. Machined from MAHLE’s exclusive stronger, lighter, low drag slipper skirt forgings, each of MAHLE’s PowerPak pistons are made in America. Additionally, the ring grooves are machined on MAHLE-manufactured machinery resulting in the flattest, best sealing ring grooves in the industry.

Each piston is dual-coated first with a Phosphate dry film lubricant to eliminate micro-welding, then the skirts are coated with MAHLE’s proprietary Grafal® cushioning, anti-friction skirt coating. Every PowerPak assembly comes complete with dual coated pistons, German steel pins, race-proven round wire locks and a performance ring set.

NHRA Super Stock Legal 5.4L Super Cobra Jet Piston Assembly

Designed to squeeze every ounce of horsepower from the Super Cobra Jet Mustang 5.4L supercharged motor, MAHLE Motorsports’ PowerPak pistons meet all NHRA Super Stock regulations, are NHRA approved and developed for maximum compression, reduced drag and increased ring seal. Machined on MAHLE’s lightweight ultra-strong forgings to exacting tolerances, the PowerPak pistons are triple coated; first with MAHLE’s proprietary Grafal skirt coating, a phosphate dry film lubricant protecting the pin bores from galling, while the top ring grooves are hard anodized to eliminate micro-welding.

Performance Piston Rings

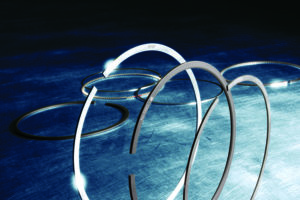

MAHLE Performance rings have been available through MAHLE Aftermarket Inc., and are now offered in a new performance package. This makes it easier for MAHLE customers to stock and sell the line. The part numbers will not change and coverage continues to grow.

MAHLE Performance rings have been available through MAHLE Aftermarket Inc., and are now offered in a new performance package. This makes it easier for MAHLE customers to stock and sell the line. The part numbers will not change and coverage continues to grow.

Being one of the world’s largest piston ring manufacturers, MAHLE can offer superior technology in products and materials at a competitive price. SAE9254 steel is the base material for most compression rings, allowing HVOF coatings and PVD coatings to be applied as the application requires. This also enables MAHLE to offer advanced designed second rings from this same steel.

“MAHLE has had the good fortune to have longstanding relationships with top racers to help develop this line,” says Jon Douglas, President of MAHLE Aftermarket North America. “We work closely with our MAHLE plants on product advancements and just as closely with top racers and performance engine builders so they can take advantage of the products we make.“

For more information, visit http://www.us.mahle.com/en/motorsports/